© 2006 All Rights Reserved. Do not distribute or repurpose this work without written permission from the copyright holder(s).

Printed from https://www.damninteresting.com/the-last-great-steam-car/

When primitive automobiles first began to appear in the 1800s, their engines were based on steam power, the same power source which had motivated the Industrial Revolution. Steam had already enjoyed a long and successful career in locomotive powerplants, so it was only natural that the technology evolved into a miniaturized version which was unshackled from the rails. But these early cars inherited steam’s weaknesses along with its strengths. The boilers had to be lit by hand, and they required about twenty minutes to build up pressure before they could be driven. Furthermore, their water reservoirs only lasted for about thirty miles before needing replenishment. Despite such shortcomings, these newfangled self-propelled carriages offered quick transportation, and by the early 1900s it was not uncommon to see such machines shuttling wealthy citizens around town.

But the glory days of steam cars were few. A new technology called the Internal Combustion Engine soon appeared, which offered the ability to trundle down the road just moments after starting up. At first these noisy gasoline cars were unpopular because they were more complicated to operate, and they had difficult hand-crank starters which were known to break arms when the engines backfired. But in 1912 General Motors introduced the electric starter, and over the following few years steam was gradually sacrificed at the altar of convenience. Even as the steam car market was briskly evaporating, four brothers named Doble made one last effort to rekindle the technology, and the vehicles they eventually produced proved to be extraordinary machines.

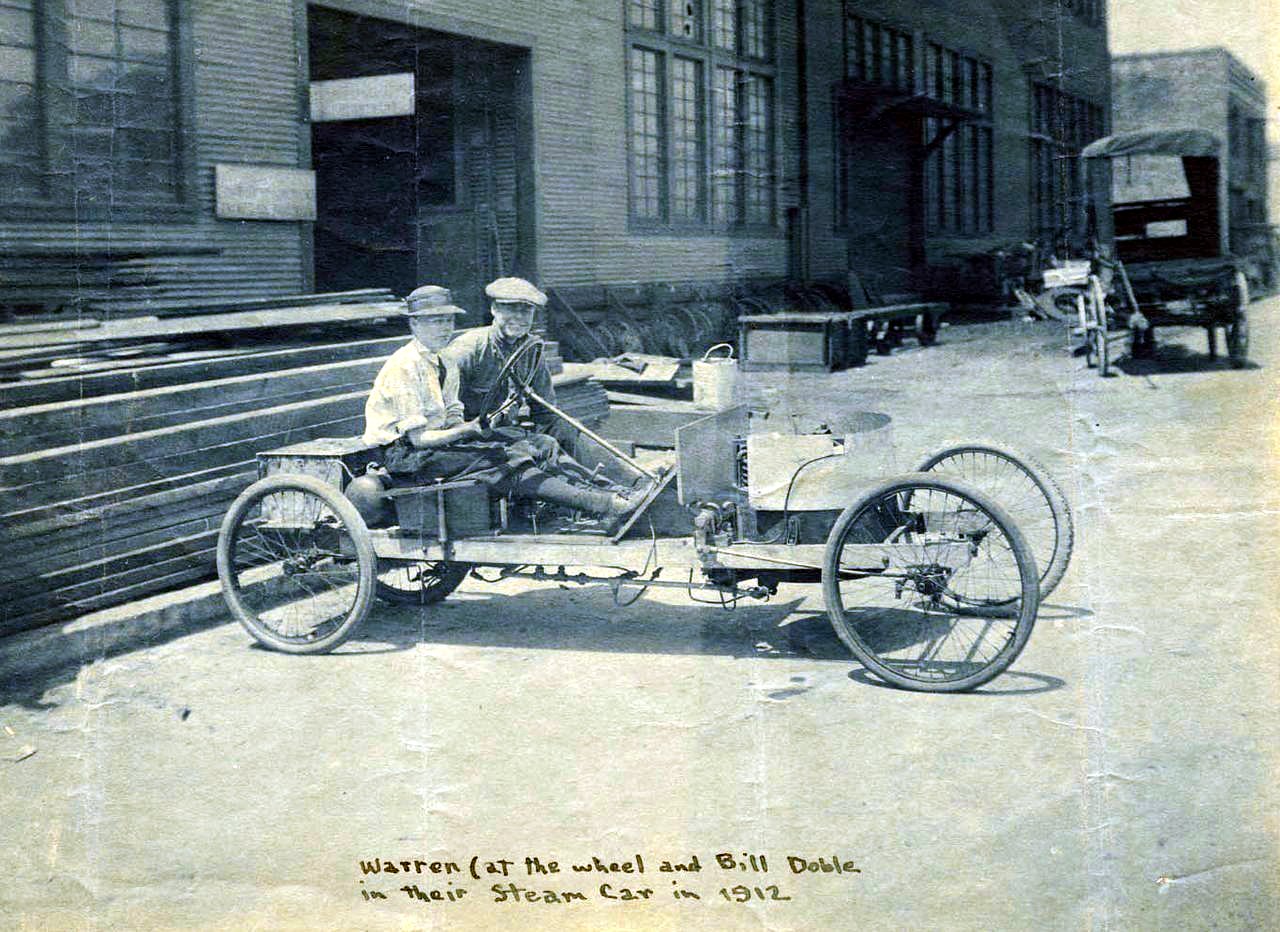

During the years between 1906 and 1909, while still attending high school, Abner Doble and and his brothers John, Warren, and Bill built their first steam car in their parents’ basement. It was comprised of parts taken from a wrecked White steamer, but reconfigured to drive an engine of their own design. Though it did not run well, the Doble brothers went on to build a second and third prototype in the following years, further re-imagining the steam car concept that the auto industry had abandoned. Their third prototype— nicknamed the Model B— led Abner to file a handful of patents for the related innovations, including a water-condensing system which allowed the water supply to last about 1,500 miles in contrast to a typical steamer’s 100 miles. The Model B design also protected the boiler’s internals from rust and scale by mixing the engine oil with the boiler water, thus resolving a common steam car nuisance.

Though the Doble boys’ prototype still lacked the convenience of an internal combustion engine, it drew the attention of automobile trade magazines due to its numerous improvements over previous steam cars. Aside from the slow startup time, the Model B proved to be superior to gasoline automobiles in many ways. Its high-pressure steam drove the engine pistons in virtual silence, in contrast to clattering gas engines which emitted the aroma of burned hydrocarbons. It also had no clutch or transmission, because the full energy of the stored steam pressure was available at all times. Perhaps most impressively, the Model B was amazingly swift. The prototype could accelerate from zero to sixty miles per hour in just fifteen seconds, a feat described as “remarkable acceleration” by Automobile magazine in 1914. The contemporary Model T from Ford took about forty seconds to reach its top speed of 40-50 miles per hour.

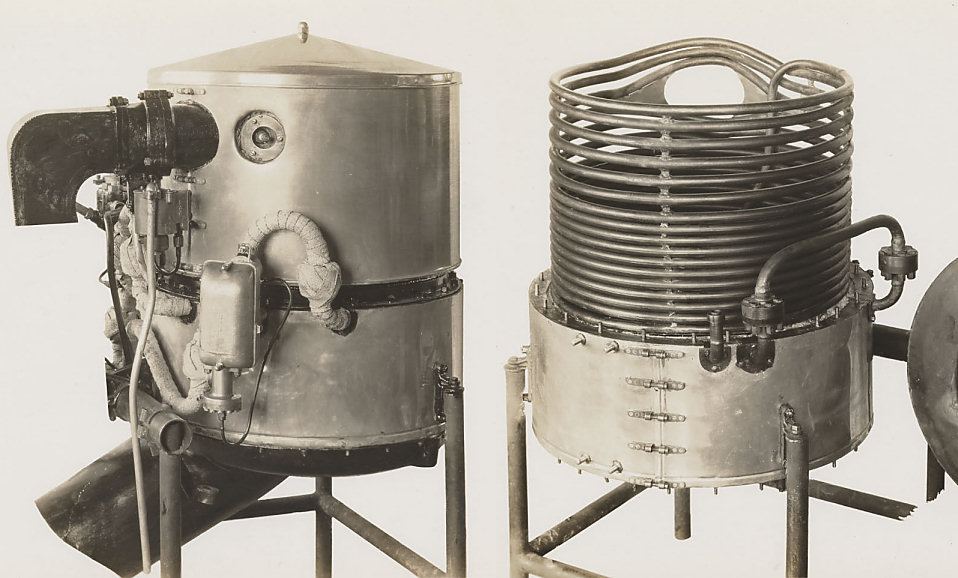

The following year Abner drove his Model B from Massachusetts to Detroit in order to seek investment in his automobile design. He managed to scrape together $200,000, which he used to open the General Engineering Company. He and his brothers immediately began working on the Model C, which was intended to expand upon the innovations of the Model B. The brothers added a key-based ignition in the cabin, eliminating the need for the operator to manually ignite the boiler. John Doble— perhaps the cleverest engineer in the family— also devised a flash boiler system where kerosene was atomized and ignited with a spark plug, which then rapidly heated the water inside coiled steel tubing. This change allowed the new Doble-Detroit to be ready to drive in as little as 90 seconds after ignition. With these improvements, the Dobles’ new car company promised a steamer which would provide all of the convenience of a gasoline car, but with much greater speed, much simpler driving controls, and a virtually silent powerplant.

In January 1917, Abner Doble decided to enter his unusual new car into the annual National Automobile Show in New York. Almost 100 new cars were on display at the influential convention, and the Dobles’ was the only steam car among them. Nevertheless, each day the modern prototype drew a crowd of onlookers, which underscored the public’s eagerness for something better than the persnickety clutch-and-transmission contraptions they’d been driving. Doble’s car was not only more powerful, but it had only four drive controls: a steering wheel, a brake pedal, a reverse pedal, and a hand-operated throttle knob. By the following April, the General Engineering Company had received 5,390 deposits for Doble Detroits, which were scheduled for delivery in early 1918.

Later that year Abner Doble delivered unhappy news to those eagerly awaiting the delivery of their modern new cars. After building just eleven of the Doble-Detroit steamers, the company had imploded. Abner publicly put the blame on steel shortages due to the ongoing World War, however this explanation proved to be a fiction he had manufactured to conceal the true reason for the company’s demise: the Doble-Detroit was mechanically unsound. Those customers who received the handful of completed cars complained that the vehicles were sluggish and unpredictable, sometimes going in reverse when they should go forward. The new engine design, though innovative, was still plagued with serious glitches. Furthermore, the Doble family was bitterly divided over Abner’s insistence on publicly taking credit for all of the company’s technical achievements, even those rightfully belonging to his brothers. John eventually reached a breaking point and sued Abner for patent infringement, and a castigated Abner left Detroit to move to California.

The event might have vaporized the brothers’ steam car dreams had it not been for John’s untimely death a few years later. He died of lymphatic cancer at age 28, an event which reunited the surviving brothers for one final attempt to produce a viable steam automobile. They established Doble Steam Motors in Emeryville, California, and began working to resolve the shortcomings of the Doble-Detroit. The three men redesigned the boiler to further improve its reliability and performance, and reworked the steam-driven piston engine to have both high-pressure and low-pressure cylinders. The engine was integrated directly into the rear axle, so there was no need for a drive shaft. With no clutch, transmission, or drive shaft, the Model E was a very straightforward machine with only twenty-five moving parts in the entire drive train. Fully loaded with kerosene and water, the new Doble car weighed about 5,500 pounds, which is roughly equivalent to a modern Ford Expedition.

In early 1924— over ten years after the unofficial demise of steam technology— the Doble brothers shipped a Model E to New York City to be road-tested by the Automobile Club of America. After sitting overnight in freezing temperatures, the car was pushed out into the road and left to sit for over an hour in the frosty morning air. At the turn of the key, the boiler lit with a throaty burst reminiscent of a gas furnace, and the gauges began to twitch. The boiler reached its operating pressure inside of forty seconds, and the driver experimentally turned the throttle knob on the steering wheel. With a low hum, the car’s steam engine briskly pushed the vehicle forward with 1,000 foot-pounds of torque, smoothly accelerating the car and its four passengers to forty miles per hour in just just 12.5 seconds. As they drove the test vehicle further, they found that its evenly-distributed weight lent it surprisingly good handling in spite of its great mass. The onlookers were understandably quite impressed. The only notable shortcoming was its mediocre braking performance, but this flaw was eclipsed by its massive, silent power and graceful handling. It seemed that the the Doble brothers were finally following through on their promise of a great steam car.

As the new Doble steamer was further developed and tested in the Emeryville factory, a lighter version of the Model E zipped from zero to seventy-five miles per hour in a jaw-dropping ten seconds. Even at such high speeds, the engine and drive train were free of noticeable vibration, and the steam piston engine was turning at a leisurely 900 RPM. The model E’s maximum speed was pushed to over 100 miles per hour, and it achieved about fifteen miles per gallon of kerosene with negligible emissions. The engine and drivetrain were solid and reliable, and due to Abner’s perfectionist nature the parts in the steamer’s drive system were machined to fit perfectly, negating the need for problematic gaskets.

Sadly, the Dobles’ brilliant steam car never was a financial success, even with its groundbreaking technology. Priced at around $18,000 in 1924, it was popular only among the very wealthy. Its acceptance was also crippled by the Dobles’ previous missteps in the auto industry, and by Abner’s relentless perfectionism. It is said that no two Model E’s were quite the same, because he tinkered endlessly with the design. The brothers might have been able to resolve such issues, but they were undone by Abner’s tendency to stretch and bend the law in much the same manner as he did technology. In 1924 the state of California learned that he had helped to sell stock illegally in a desperate bid to raise money for the company. Though Abner was eventually acquitted on a technicality, the company folded during the intervening legal battle. Fewer than fifty of the amazing Model E steam cars were produced before the company went out of business in 1931.

Abner went on to work as a consultant for other automakers all over the world. For his whole career, until his death in 1961, Abner Doble remained adamant that steam-powered automobiles were at least equal to gasoline cars, if not superior. Given the evidence, he may have been right. Many of the Model E Dobles which have survived are still in good working condition, some having been driven over half a million miles with only normal maintenance. Astonishingly, an unmodified Doble Model E runs clean enough to pass the strict emissions laws in California today.

Several automakers continued to experiment with steam until 1973, when the Arab oil embargo forced them to concentrate resources on the problem of fuel efficiency in existing engines. Since that time, not many manufacturers have put much research into a car powered primarily by steam. It is true that the technology poses some difficult problems, but one cannot help but be curious how efficient a steam car might be with the benefit of modern materials and computers. With today’s pressure to improve automotive performance and reduce emissions, it is not unthinkable that the steam car may rise again.

© 2006 All Rights Reserved. Do not distribute or repurpose this work without written permission from the copyright holder(s).

Printed from https://www.damninteresting.com/the-last-great-steam-car/

Since you enjoyed our work enough to print it out, and read it clear to the end, would you consider donating a few dollars at https://www.damninteresting.com/donate ?

first commenter! Woohoo!

I think that the steam cars may already be on their way back… in the form of a hybrid. I recall seeing an article elsewhere a few months ago about someone who put an extra cylinder into an engine block that was a steam piston run off the waste heat from the other cylinders. This eliminates the need for a radiator in the car, as the engine is cooled by this steam cylinder being fed water continuously, but you would have to stop and fill up with water as well as gas. (how long would it take the build the infrastructure to distribute that?)

Ok, I tracked down the article… it was BMW that is working on the idea. Here’s the link to the story:

http://www.treehugger.com/files/2005/12/bmw_developing.php

Drakvil said: “but you would have to stop and fill up with water as well as gas. (how long would it take the build the infrastructure to distribute that?)”

Most (all?) garages/service stations offer water already though for topping up your radiator..?

Or did you mean some convenient, combined pump?

I think he means distilled water, which would be more ideal for this type of application.

I remember reading some article about instead of adding a spare cylinder to the engine, to use water in the existing cylinders.

Instead of the usual two up and down movements (fill up with fuel in the first one, combustion=power in the second one) you would simply add a third stroke to it where water is injected, evaporates due to the heat and thus produces a second (steam-)power stroke in the engine. Not only would this provide extra power from the engine without using up extra fuel, but it would also cool the engine in the process.

patrick_k_o said: “I remember reading some article about instead of adding a spare cylinder to the engine, to use water in the existing cylinders.

Instead of the usual two up and down movements (fill up with fuel in the first one, combustion=power in the second one) you would simply add a third stroke to it where water is injected, evaporates due to the heat and thus produces a second (steam-)power stroke in the engine. Not only would this provide extra power from the engine without using up extra fuel, but it would also cool the engine in the process.”

I heard about this too. I think you are talking about a 6 stroke engine instead of a 3 stroke engine. Most engines have 4 strokes: Intake, compression, power and exhaust. In a 6 stroke engine, water is injected into the cylinder after the 4th stroke, and it expands into steam to produce a second power stroke. After that a second exhaust stroke pushes the steam created out of the cylinder.

What a wonderful article, I consider myself a bit of a car buff, but had never heard this story!

Very nicely done!!

As I was reading this article, I kept imagining what an efficient, clean, and economical vehicle this could become with today’s technology. Imagine going 1,500 miles on a single fill-up! It could also burn compressed natural gas instead of kerosene. Not only would CNG burn more cleanly, but there are actually CNG gas stations in some locations.

See http://www.stanleysteamers.com/doble_paper.htm for Abner Doble’s paper on Steam Motor-Vehicles.

I too remember reading about the 6-stroke engine and I would like to know how the guy prevents the water and oil from mixing. I have not read anything that explains how/if he does this.

I’m amazed that these guys got the engine to go from cold start to moving in less than a minute. The overall improvement to the engine is quite impressive, especially for their time. Too bad it was 50 years too late.

Agreed, 50 years too late. Like so many innovations, it just came too late, and also succumbed to people’s inability to separate the technology from the personality of it’s developer. The performance of this thing sounds as good as any you’d really need today, and sounds superior to electric cars to me.

I didn’t know anything about Abner’s brothers, but I do know they drove the Stanleys crazy!

Someone in Atlanta has a steamer they drive long distances and frequently (maybe a Jackson?). An amazingly silent, smooth, beautiful behemoth.

Thanks for the damn interesting article!

Buckelew

1965 Chrysler Newport Convertible

1965 Chrysler 300L

1967 Cadillac Deville Convertible

1968 Cadillac Deville Convertible

1919 Doble (I WISH!!)

Just think about what aerodynamics and weight reductions could do for this car. The doble brothers were able to get a 5500 pound brick up to 100 miles an hour. I know pretty much nothing about steam engines but i bet with todays technology we could reduce that thing to at least 2500-3000 pounds, and knock off about 80 to 90% of the drag on that car.

A website called intereting thing of the day? Sounds like trouble is a-brewin’. A-BREWIN’ I SAY!!!

Also, if I remember my Mythbusters correctly, I thought it had been discovered that distilled water doesn’t boil. I heard it needs impurites in order to boil, otherwise when you put it in the microwave, it will become super-heated as the temperature of the water reaches well above the boiling point, until it loses its stability and quite literally explodes the instant anything such as metals touch it. (actually, this would be a great way to use water in explosive applications)

Very Interesting article, by the way.

Oh also…

HEY! Somebody fixed the multiple paragraph thing in the preview option!

.H

……O

…………O

………………R

……………………A

…………………………Y

………………………………!

Imagine having 1000 ft-lbs of toque instantly available in a car today. Maybe it’s a good thing that I’m only imagining it…

Distilled water boils just fine. The phenomenon that the Mythbusters guys observed is called superheating. Tap water in the microwave will do the same thing. In the microwave, there is little or no convection because the heat source is, effectively, the water itself. Put distilled water on a stovetop (or over a heater in a steam boiler) and it boils just fine. The water needs convection or some reasonably large particles to get the boiling going at 100C.

Also, don’t confuse boiling with steam. When distilled water hits 100C, it turns to steam. In the microwave, you just may not see any bubbles.

How much torque does a good sized electric motor make?

And electric motors make 0 (thats a zero not an o) rpm torque, negating the need for a transmission alot of the time. For example, the GM EVs, it’s been years but I believe the gen2 had a 4 speed manual trans, but most just put it in gear and left it there because it made so much 0rpm torque.

So, is anybody working on this obvious competitor to gasoline-powered automobiles? The applications would go well beyond cars, with the torque that could be created and surely there are current uses of steam that could be modified and improved upon without starting off where these guys got stymied, uses of ceramics and other modern materials that have already been adapted to steam in dams or power stations or some such. Aren’t there things like steam shovels and steam-powered trains that kept the effort evolving?

To cornerpocket:

Yes, there are people working on better alternatives, not enough though (IMO).

For example, for people who haven’t heard yet, Tesla car company is making a really nice Electric Sportscar.

Here are some specs:

– 250 miles per charge.

– 0-60 mph in 4 secs.

– 2 gear transmission only (2nd gear is only needed when going top speed only)

– Around 100,000$ – not that bad for 0-60 in 4 secs sportscar/roadster considering this:

– Approx. cost is 1 penny per mile (as opposed to 10 – 25 cents per mile for gas cars).

– Virtually no maintenance needed, no oils to change, no air filters, etc…

– Batteries last over 100,000 miles, even after that it’s still usable, just with less capacity.

…anyway, I think this is a very good and impressive start for one of the first succesful EVs. their website is teslamotors dot com

What a shame this isn’t the current technology that we are using today, instead of the horrible, carbon-spewing machines we drive everywhere in. Still, here in Australia there is a massive water shortage (we are on stage 3 water restrictions, meaning no watering a garden or grass, and no washing of cars) so it might not be the perfect way. Although, if the water is released as steam then it would rise into the atmsphere and come down as rain, right? Correct me if I’m wrong.

Scharneeigh said: “What a shame this isn’t the current technology that we are using today, instead of the horrible, carbon-spewing machines we drive everywhere in. Still, here in Australia there is a massive water shortage (we are on stage 3 water restrictions, meaning no watering a garden or grass, and no washing of cars) so it might not be the perfect way. Although, if the water is released as steam then it would rise into the atmsphere and come down as rain, right? Correct me if I’m wrong.”

Yes it would, but not necessarily in Australia :P.

Is it just me or do other people get just a little frustrated at the fact we have the capability to produce highly efficient electric/steam vehicles and yet the government is sitting on their collective hands because there’s to much to be made of taxing the people who have to drive. Seriously damn interesting article though …. no surprise for this site. Briliant work!

I had an idea of a new car to manufacture but i not gonna say coz u will steal my idea :P

newho…it would be a good idea to bring back those steam powered cars becoz they good for the environment and they quiet so u can sneak up behind sumone and HONK! the horn :D

YAAAAAAY!!!…damn interesting is such a cool website… WOOT!!!

to those engineering-minded among you; is there any good reason why these would not be suitable for use today? they sound very clean and efficient from what alan has described.

Alternative powered autos include the 1960’s experimental and nationally tested Chrysler Turbine. Basically like a jet engine, this fascinating auto ran on a variety of fuels. It, too, was quiet and heated up instantly. One drawback was what folks considered a sluggish acceleration. Only two people in each state were selected to test drive a vehicle for several months. My former neighbor was one such person. Several years ago, a rare, working example was touring in Kansas City and we made the trip to see it. My neighbor knew all about the car and he demonstrated its stability by placing a nickle on its edge on the running turbine. Unfortunately, the concept did not go beyond the national testing stage and nearly all cars were scrapped. The surviving example we saw was one from the National Transportation Museum in St. Louis.

As for the steam concept, one would hope it would develop as a viable alternative. Just as technology has reduced bulk and components, there is potential. After all, who would have though some of those bulky and inefficient electric cars of a few years ago would progress to the modern day hybrids.

orc_jr said: “to those engineering-minded among you; is there any good reason why these would not be suitable for use today? they sound very clean and efficient from what alan has described.”

A couple of reasons come to mind:

1. Steam engines will always weigh more compared to the same horsepower gasoline engine. A lot more.

2. To achieve high efficiency in a steam engine, you need all sorts of accessories like reheaters and condensers, and these are impractical to put onto a small engine like this. Same goes with steam turbines. This is incidentally why steam engine locomotives were replaced with diesels.

3. I also think safety is a concern. Steam engines are using high pressure tanks and they weigh a lot. If it explodes in an accident or from a malfunction, you are dead.

Currently, I think the most efficient thing you can get that would fit into a car would be a turbine engine (Chris describes one prototype car that uses this). There are several people online who modify cars to use these. You can even buy turbines on ebay relatively cheaply. There were several car makers toying with mass producing these, but for whatever reason, it just wasn’t viable.

As for electric cars, I wouldn’t count on them anytime soon. The battery technology has a long ways to go before it’s practical. By my calculations, batteries are at about 5-10% of the energy density required to compete directly with gasoline. I don’t know too much about the tesla car, but I know about other high performance electric cars, and they are impressive, but all the high performance ones I’ve seen (And the tesla car included) run on Li-ion batteries. This basically means your car is useless after 5 years. Getting it running again will mean buying another huge (And expensive) battery pack.

SparkyTWP said: This basically means your car is useless after 5 years. Getting it running again will mean buying another huge (And expensive) battery pack.”

That is true, but most people trade in their car after 3-4 years. However, the dealer would then have to replace the batteries anyway, so you might not get very much on trade in, but I don’t know what percentage of the cost of the car is in batteries.

The company that makes the Tesla is also going to produce a sedan, I believe. It it supposed to cost about the same fuel wise even though it will be less aerodynamic due to (they hope this happens) increase in battery efficency.

Zamemee said: “That is true, but most people trade in their car after 3-4 years. However, the dealer would then have to replace the batteries anyway, so you might not get very much on trade in, but I don’t know what percentage of the cost of the car is in batteries.”

To give a comparison: I used to work on a solar powered car. A Li-ion battery pack for it (Effectively for a

I’m not biased against electric cars, I think they’re great and they will be practical eventually (For the same amount of energy, electricity is about half the cost of gasoline). Battery technology just sucks at the moment. It’s not a government conspiracy, it’s not oil companies or large corporations holding them back, it’s just the limitations of current technology. I guess I should also mention here that fuel cells are not the answer, and will not solve this problem at all.

Yeah, my bad. Here’s the first paragraph:

To give a comparison: I used to work on a solar powered car. A Li-ion battery pack for it (Effectively for a less than 500 lbs car) that wouldn’t even last very long per charge was on the order of $4000. I’m speculating, but I would guess that for that tesla sports car, at least 1/3 of the cost is just batteries. So every 5 years, you’re looking at least $30k to keep driving an initially $100k car. If the car depreciates at the same rate as a typical sports car, the battery pack could be worth more than the car by then. BTW, I would think that the sedan would be more aerodynamic since you don’t need a huge radiator to cool the motor, so you don’t need your whole car to act as a scoop to bring in air, but again, I don’t know much about this car.

psyOtic said: “Is it just me or do other people get just a little frustrated at the fact we have the capability to produce highly efficient electric/steam vehicles and yet the government is sitting on their collective hands because…”

Why is the government supposed to be the ones making electric/steam vehicles? They’ve never made cars before. Companies make cars, people and the government(s) then have the option to buy them, so other companies want to make them to get the money. The government does have incentives in place to encourage the development of these vehicles, and even Edison was in on the act putting electric vehicle charging stations all over So. Cal. GM killed the EV 1 because it just didn’t make enough of a profit for them, and they like making the gasoline cars. They could point to the EV 1 and say “see, we made the attempt the government wanted us to, but it didn’t work – it was a failure!”. Never mind that almost every person who leased one wanted to buy it, GM wouldn’t sell them and even threatened legal action against the people who didn’t want to return them. Then GM crushed them all. If more people bought stuff like the Tesla and the Wrightspeed, the major automakers would start to fall in line and actually work on producing vehicles like that.

Mostly, you are carrying a finite amount of water and the system can only get so hot before something breaks(heat->pressure). This means you have to get rid of heat all the time; you don’t want to dump water to do so, so you need a radiator/condenser. That component can only be so big, limiting the performance of the overall system. The amount of energy you can put in ends up limited by the amount of energy(heat) that you can dump.

…now, now…let’s not all get steamed up about Dobles, Stanleys or other steam cars.

Everything…and let me repeat that…EVERYTHING…has a tradeoff.

If it’s not vehicle weight or high pressure, it’s going to be extremely flammable fuels. If you can get the power, you probably won’t be able to get performance, distance or acceleration. Oh, and let’s not forget, it’s suppose to be environmentally friendly to pacify the tree huggers…and that’s a project killer sometimes.

You want an electric car because it’s pollution free? No…you just moved the point of pollution to another location whether the energy is produced from fossil fuels or natural gas because of combustion by-products. Nuclear energy…radioactive waste. You may get a free meal, but as the saying goes…there are no free lunches.

There may be alternatives today, but they are not economically feasible or can’t be mass produced. We may get there someday, but more research is needed….and research costs money.

another viewpoint said: “You want an electric car because it’s pollution free? No…you just moved the point of pollution to another location whether the energy is produced from fossil fuels or natural gas because of combustion by-products.

However, generally munincipal power plants are a good deal more efficient then internal combustion engines, meaning less net pollution per mile driven. Not to mention you can get solar chargers for those cars.

7HS said: “However, generally munincipal power plants are a good deal more efficient then internal combustion engines, meaning less net pollution per mile driven. Not to mention you can get solar chargers for those cars.”

Yes, there are many good energy sources to power electric cars– solar, wind, nuclear, coal, hydroelectric, etc. The whole point is that we diversify sources of energy to get away from the accursed petroleum. From an energy source viewpoint, petroleum has been as close to a “free lunch” as you can get. (AND, it still is!) Environmentally speaking, there is no free lunch. (Solar, maybe, comes close.)

Steam cars appeal to me for a number of reasons: 1) The absolute simplicity of the mechanical systems. 2) the mechanical efficiency of the system. No transmission, all the torque is available at low RPMs. 3) you could (theoretically) burn anything as fuel–gasoline, fuel oil, motor oil, vegetable oil, coal, wood, corn, alcohol, petroleum coke, autumn leaves, … A steam powered semi-tractor trailer would be cool. No gears!

Corn is an interesting option for fuel. Why go through a close to break-even process to make ethanol when you can burn the corn directly? Maybe not as a convenient fuel for steam cars, but it is a neat alternative for home heating.

WOOT indeed!

Solar charging a 50kWh battery pack (The capacity available in the tesla motors car) would take you over a week unless you had a monstrously huge panel. Even if you had 100% efficient solar cells, solar powered cars will never be practical, unless you don’t mind letting it charge 90% of the time.

SparkyTWP has some good points, but he is likely from the old-school of engineering that assumes “If I haven’t thought of it yet, it likely is not possible.”

There are plently of new and old technologies not employed today’s vehicles simply because of greed and sloth in the industries and interests that stand to profit from maintaining their strangleholds.

Objective evidence more than suggests (rather it indicates) that practical full-sized vehicles have been DESIGNED and PROTOTYPED with SIGNIFICANT gains in efficiency. Whether referring to alternative fuels, electric, solar, hybrid or just better utilization of the common 4 stroke engine, concepts have already been proven and groundwork laid out. As for conspiracies … one can only infer. I think it might just be common greed within those industries that give the appearance of a united cause to screw over the consumer.

Do a simple GOOGLE or YAHOO search and you will find several full sized vehicles capable of 150MPG and better. Do not believe the lie that selling such a vehicle to the public would be impractical because of insane cost. Any auto maker has the resources to mass-produce whatever components it might state is not feasable and that should easily drive down costs. If done right, the components in question can even be designed and outfitted so that they have multiple applications, so that they are standard and cost even less – a basic concept that any industrial engineer is familiar with.

Sparky, get a new job.

We Americans are but about 5% of the worlds population yet we consume over 50% of the world’s energy. Does anybody wonder why we are the targets of terrorists and mocked by third-world nations?

Bear in mind that American productivity is way out of proportion to our numbers too. It takes a lot of energy to accomplish what we–and sometimes we alone–can do. (Now, that’s not to say that there is not a lot of waste; there certainly is, and it needs to be significantly reduced. But, still, don’t diss America out of hand.)

What we do is for ourselves. What we can’t do as cheaply as others, we have outsourced to China or India. That isn’t truly “America” though. It’s corporations doing what they can because a lack of government regulation allows it. As we continue to move towards a service-based economy, our dollar will continue to drop in value, unless said services are the type that increase the standard of living. By what rubric do you measure standard of living. I would prefer to live underneath a giant mushroom like the smurfs. Those blue things are awesome!

All that said, don’t take me seriously. I’m not really that smart.

Nutramistic, I agree with you…. you’re not really that smart.

Check out http://greensteamengine.com for a new twist (!) on steam engines.

well, here i am way down at the bottom – i think forums like this should post the most recent comment at the top… just from a design standpoint – anyway, yes steam is an awesome technology. prooven, yet forgotten by money. go see Harry’s stuvv in florida: http://cyclonepower.com/

Steam is the better power plant for automobiles. Those who disagree most often do not understand steam, and/or they are biased in favor of other options. Steam solves all of the problems presented by the alternatives. The primary issues are performance, range, efficiency, emissions, reliability, longevity, safety, fuel availability. Let’s compare:

Electric cars get points for performance, emissions, reliability, and fuel availability. Efficiency is lacking. One person here argues that municipal power plants are more efficient implying that the electric car is on net balance more efficient. Not quite. There are an average of 30% transmission losses from power plant to battery charger. Battery charger sees additional 10% loss. Batteries themselves only deliver about 75% of the energy used to charge them. Motor controller has losses and motor has losses. Therefore, on net balance the electric car is seeing about 15% efficiency at best. Then there are other problems to contend with…. the range of the electric car is limited, batteries take time to charge, batteries must be replaced and they are expensive (they are also toxic). So, as one person emphasized here, there is always a trade off. In many niches the electric car may be a good solution, but the idea that the majority of persons should go electric is just absurd. Remember, passionate issues require dispassionate analysis. I’m just being objective.

How about hybrid cars? Well, I’m not a huge fan of hybrids for a variety of reasons. There is added complexity. A hybrid is basically a standard automobile with lots of additional components. Not my idea of elegance. However, I do believe that a series hybrid car (like the Chevy Volt) is a step in the right direction. We still have the internal combustion engine with the fuel limitations, expensive emissions controls, and nasty emissions. The overall complexity remains high, but not so much as parallel hybrids. The fuel cell solves some problems, but presents more including more limitations on fuel availability.

Now consider a modern steam engine. I invoke the Cyclone Engine (see previous post) for reference. Let’s look at performance, range, efficiency, emissions, reliability, longevity, safety, fuel availability.

1. Performance – Similar to a two stroke gasoline engine, but starting torque is far greater (and Cyclone is FAR less noisy). A 100 hp Cyclone has a starting torque of 700 ft lbs. The torque profile is like a gas engine’s flipped backwards…. torque is highest starting out and falls, but always remains at least twice as high as a 4 stroke gas engine at the same speed and rated power. The torque curve is such that a transmission is NOT required. Engine is self-starting (can operate at 1 rpm up to 3600 rpm). Engine can even reverse itself. A Diesel automotive power plant (including all auxiliaries…. transmission, emissions controls, radiator, starter motor, flywheel, etc.) with the same power as a Cyclone automotive power plant weighs 2.5 times as much as the Cyclone.

2. Range – Higher efficiency and ability to use fuels with greater energy density will extend range relative to gas autos.

3. Efficiency – Measured at 36% thermal efficiency…. roughly equivalent to Diesel engines. However, there are fewer power transmission losses because, well, NO transmission is required, only a much simpler gear box.

4. Emissions – With no emissions controls at all (no computers, sensors, catalytic converter, etc) the emissions are far lower than the cleanest internal combustion engine. Additionally, nitrous oxide emissions are virtually nonexistent. The Cyclone passes CA smog standards for the year 2020, and with NO modification.

5. Reliability – A Cyclone automotive power plant has less than 1/5 the parts count of a standard automotive power plant (including power transmission equipment). The 6 cylinder radial Cyclone has one cam to operate all 6 inlet valves and there are NO exhaust valves. There is a single thermostat to control boiler temperature (50+ year old technology), and a single electric motor driven blower fan. Steam generator, condenser, and auxiliary heat exchangers are simple and integrated with the engine. Peak engine temperature is 1200F vs nearly 2500F in internal combustion. Average speed is lower. Engine cylinders and bearings are WATER LUBRICATED. NO OIL CHANGES! Water and steam is in a closed system…. no adding water, either!

6. Longevity – Lubricating quality of water and the composite materials used in the Cyclone is the same as oil lubrication in internal combustion engines, but there is NO fouling of the system as seen in internal combustion. The closed system of the Cyclone is always clean. Additionally, operating temperatures are lower in the Cyclone and average speed is lower.

7. Safety – The power plant itself is perfectly safe. But more importantly, the high power to weight ratio and CRAZY torque provides no need to compromise on vehicle safety (like electric cars and hybrids often do). One great application for the Cyclone is the trucking industry and earth moving equipment.

8. Fuel availability – The Cyclone truly shines here! The Cyclone has been operated on the following fuels (so far) with no modification to the engine: gasoline, ethanol, E-85, diesel, biodiesel, SVO, fuel oil, kerosene, orange oil, acetone, propane, butane, hydrogen, crude oil… the engine has even operated on solid fuels including coal dust and wood flour. Additionally, there is no reason at all why a biomass gasifier cannot be used as well (wood chips, wood pellets, paper pellets, seaweed pellets). For stationary applications (a generator for example) the Cyclone can also operate using concentrated solar (a Cyclone has been operated by heat lamps just to illustrate the concept).

I can go on and on, but it should be a slam dunk. Steam is the way to go… and we’ve only scratched the surface of its potential.

Witht he recent interest in alternative energy and hybrid vehicles the Doble and similar vehicles are getting notice. In the 1/08 issue of Hemmings Classic Car there is a great article on the 1925 Doble. Additionaly there is a blog http://www.route66chronicles.blogspot.com with lots of articles on similar cars.

check out the” bullet engine” designed by kasmericz holubowicz off google search that claims to capture 92% power conversion using 12 stroke high torque “bullet” type explosion technology.

I also think a dobie like steam conversion for home wood burners could capture heat losses, while generating electricty and hot water.

any other dobie like engine conversion stories out there?

Jeff

mariasman is the only one who mentioned it…..biomass gasifier. Literally millions of vehicles have run on wood/coal/biomass gasifiers, go to woodgas’dot’com for more info. Use woodgas to run a generator and you can charge your electric vehicle batteries every day. I cook with a woodgas stove – it generates a s#@tload of heat just using the brush, trimmed branches, lawn clippings, coffee grounds and banana peels I throw into it. Besides that, it’s just fun to use (okay, I’m a closet pyro :-)). For a stationary ICE, say pump or generator, woodgas is great, a bit (i.e., a LOT) more difficult to adapt to a motor vehicle. Combine that technology with steam and you might really have something.

Maybe steam has another chance. Check out http://www.brashengines.com to see the Air Steam Hybrid that eliminates the start up delay and large boiler! It’s got a small working prototype and a new contract from DOT to help with development.

Dear Steam power inventors;

06-02-2010

I found an idea about a “Hybrid Steam Six Cycle Engine” by Bruce Crower in “The Best Inventions Of 2007” on the Internet. The present “Gulf Oil Spill” has set me off again to try to get a proto-type engine built of a hybrid steam engine.

I have been writing in my journals for 30 years about a conversion I wanted to make to the gas guzzling V-8 engines. My idea has been to use two outside cylinders on one side as gas cylinders without modification. The other side inside cylinders would also be used as gas cylinders without modification. These four cylinders would be modern fuel injected with all normal computer controls. The engine must be run on these four cylinders until proper block and head temperatures are achieved. Then the four remaining cylinders would be run as two stroke units being powered by “flashsteam” injection at top dead center of the steam cylinders. The exhaust from each gas cylinder would go out of its normal exhaust port and loop around to its adjacent steam cylinder old exhaust port. The old exhaust valve and seat in the steam cylinder will be replaced with a “heat sink” which extends into the old combustion chamber and thereby replacing it. The other side of the “heat sink” will have fins on it extending up through a hole milled in the head which replaced the old exhaust valve. A stainless steel tube will be press fitted in that hole which holds that “heat sink” essentially blocking any flow into the steam cylinder. But the exhaust gas from the adjacent gas cylinder will flow through a side hole in that SS tube with the fins of the “heat sink” protruding upward. This new exhaust tube will have to come out of a hole cut in the old valve cover. There will be two such holes in the old valve covers directly in line with the replaced old exhaust valves. The original intake valves of the converted cylinders will become the new exhaust valves for the new steam cylinders. They must be controlled by a special cam shaft which has a double lobe for each of the new steam exhaust valves. This control will be to open the steam exhaust valve at bottom dead center and close it on top dead center using two new lobes on that cam position. There will be four such new double lobe cam positions. The original exhaust lobes for those cylinders will not be used. A new simplified intake manifold must be fabricated to provide normal injector placement and connection to the throttle body for the gas cylinders. A new manifold from the original intake holes on the steam cylinders which are now steam exhaust holes will be joined to the new SS gas exhaust tubes coming out of the valve covers which will mix the spent steam with the gas exhaust to be outputted to the atmosphere through normal modern exhaust systems. A computer control of the “flashsteam” injectors must be provided. The idea of using a “Corn Burner” as a heat source has been modified by using the waste heat from the standard internal combustion engine. I am not mixing water or steam into the gas cylinders. The gas cylinders will be unchanged physically or in their normal operation; just their exhaust will be diverted a bit. Limiting some of the water cooling around the new steam cylinder and head should be done to retain their heat. The “flashsteam” injector may be the proper way to run the steam cylinder. I have wanted to make what I call my “Hybrid Steam Engine” for years. Every time the price of fuel goes up, I get more interested in its development. Now the fuel price has pushed me to accomplish my goal. But I do not feel the idea or which could be an invention needs to be held in private for financial gain. I have told many people about the idea without any action. Now with the Internet, maybe this idea will catch the eye of people of the World and not be squashed by the oil companies.

Attention: V-8 Engines, it is time to change your eating habits. You are going to have your gut detoured to scavenge some of your waste heat. You are not going to have to use four of your gas cylinders on your eight cylinders engines to run any more. You can have four cylinders with gas; but the other four cylinders will provide power without you expelling hot air. The four converted cylinders will not be letting out your energy just to raise the air temperature around you.

Attention: Drivers of V-8 Engines, do your part to encourage the development of a more efficient internal combustion engine. Be at least interested in ideas to ultimately save your cash and our energy supplies. Enthusiasm is the spice of life; and it will provide rewards. That is better than complaining over a cup of coffee. Positive feedback with constructive criticism is what we inventors need to put our ideas into a working prototype. At least, you can see from my contributions that I am attempting to help our energy situation with positive suggestions.

Attention: Inventors, car buffs, steam engine masters, and others with positive feedback, make your contribution to an energy efficient internal combustion engine. Remember, it doesn’t have to be something that needs new castings. Electronic control is common place now. Rust resistant injectors are available. Bring up your problems with the idea in a positive way with alternative approaches. Let us all work toward a common goal which is to finally keep more of our hard earned cash in our pocket instead of paying through to nose for our fuel to propel our vehicles.

Attention: Big SUV and pickup drivers, wouldn’t it be wonderful to take your gas guzzler vehicles into a modification shop to have it converted to a hybrid steam engine. There is enough carrying capacity for this energy modification of your gas guzzler vehicle which is upside down in value of typically $10,000 because no dealer will give you jack poo for it toward a new small energy efficient vehicle. Talk about this hybrid steam engine idea that I have proposed. There must be engine builders to help make a prototype.

Attention: As the writer of this hybrid steam engine, I will continue to make a prototype. In my following contribution letters, I will be more specific on the necessary modifications and my progress in making a prototype. I even am thinking about making my own camshaft by wilding and regrinding four of the lobes by following the contour of other lobes which will give me necessary lobe with two high sections. I am not worrying about things like angles just as long as the valve opens at bottom dead center and closes at top dead center. The four remaining gas cylinders are 4 cycle gas engine design. The four steam cylinders are now 2 cycles with a power stroke on every downward movement of the piston. No gas is mixed with water. No worry about heat losses because that is exactly what the hybrid steam engine does to the block heat as well as the exhaust heat. As far as heat rejection, and condensers in steam engines, that will be something to consider for better efficiency and water consumption. But if all I need to do is to add distilled water to my tank and drive the hybrid steam engine to work with its normal fuel supply, I can do that. I can even collect rain water to use a water supply. As far as freezing in cold climates, that will have to be addressed in a positive way. Water getting into the crankcase from the steam cylinders must be addressed; but has anybody tried water soluble oil in their crankcase? The automatic machining industry use soluble oil in all of their high speed cutting machines to cool and lubricate their cutters. My contribution to this forum will be positive with as much help to others to keep their enthusiasm.

As I mentioned in the beginning of this letter, my thoughts of inventions has be on going for years. I do have other ideas which I would be glad to share with you. I am 71 in fair health with a strong background in electronics and CAD drawing education. My best aptitude was measured in beginning college to be mechanics and science.

There is a “Six Stroke” engine designed by Bruce Crower that has unique principles. The main important principle is providing a fifth and sixth stroke in each cylinder. I am unsure of the need of a second exhaust valve in each cylinder. The sequence of operation as I understand is to have a (1) intake gas stroke, (2) compression gas stroke, (3) power gas stroke, (4) exhaust gas stroke, (5) power steam stroke, and (6) exhaust steam stroke.

Would it be possible to make the exhaust gas valve to double for the exhaust steam valve? They are both in the same cylinder positioned probably side by side. With that design, the old gas guzzler V-8 could be easier modified. The cam shaft would have to be modified in your design to make it turn at 1/3 of the crank shaft and make the lob positioned in a 1/3 portion of the cam shaft. The gas exhaust lobe would have high spots that would open the valve on stroke (4) and stroke (6) if the same valve were used for the gas exhaust stroke and steam exhaust stroke; otherwise each cylinder must be provided with a third valve system.

If you used the common exhaust valve idea on the six stroke hybrid steam engine but add the idea of using alternative cylinders for only steam power, can the result be a big winner?

The cam shaft would need proper lobes for each cylinder based on the 1/3 cam speed. I think the cam should provide six strokes as follows:

(A) An intake gas stroke, a steam power stroke, and a steam exhaust stroke.

(B) A gas compression stroke, a steam power stroke and a steam exhaust stroke.

(C) Gas power stroke, a steam power stroke, and a steam exhaust stroke.

(D) Gas exhaust stroke, a steam power stroke, and a steam exhaust stroke.

(E) Gas (steam) power stroke, a steam power stroke, and a steam exhaust stroke.

(F) Gas (steam) exhaust stroke, a steam power stroke, and a steam exhaust stroke.

Does the combination of the “Six Cycle Hybrid Steam Engine” and my hybrid steam engine have merit? Bear in mind that this engine should be able to be made from a modified standard V-8 engine. Only the cam shaft needs to be made. The heads could be just modified heads. The exhaust manifold as well as the intake manifold is also special welded pipes. Fuel injection is standard for the gas cylinders. Water injection must be provided out of rust free material for the steam application. Gears and chains must be provided for the 1/3 ratio of cam to crank. Don’t worry about water recovery; and don’t worry about distilled water because the use of rain water or snow-melt is good enough. The emergency use of distilled water is always the possibility.

I hope my suggestions are more than hot steam. I need to put my retirement to good use to possibly help the bad economy and energy problems of our Country and World. Keep in touch because I have some other good ideas such as fine gold recovery and owner builder home construction.

Sincerely,

George J. Birds Jr.

601 Canyon Dr.

Lebec, CA 93243

Phone: (661) 248-5152

E-mail: birdsgyjk@wmconnect.com

https://www.youtube.com/watch?v=rUg_ukBwsyo

Jay Leno’s Garage episode on his E25

Jay Leno has 2: http://www.popularmechanics.com/cars/a6228/jay-leno-and-his-doble-steam-cars/

steam car are coming very soon because internal combusting engine are producing so much of pollution and steam car and solar car are going to be the feature of cars thanks

Like siddarth, I wonder how much longer the internal combustion engine will be here.

And I just on television what England intends to do with internal combustion vehicles by 2035 and 2050.

Steam cars Vs Solar Cars or Electric Cars who want to Discuss with me

Solar cars are a complete no-go. There just isn’t that much energy available in sunlight, even at noon on a cloudless summer day. The best way to operate off of solar energy is to burn wood (because cellulose, the overwhelming majority of the content of wood, is just a chemical storage of the sunlight received by the tree’s leaves, and even they reject green light, and don’t utilize anything in the infrared and lower energy wavelengths.

Now, it seems that more and more people are turning away from electric cars.

Consider Hertz. The CEO went big, bought 20,000 EVs. Now, they’re being sold, and Hertz will buy more combustions. Also, the CEO was fired yesterday.

Now, it seems that more and more people are turning away from electric cars.

Consider Hertz. The CEO went big, bought 20,000 EVs. Now, they’re being sold, and Hertz will buy more combustions. The CEO was fired yesterday.